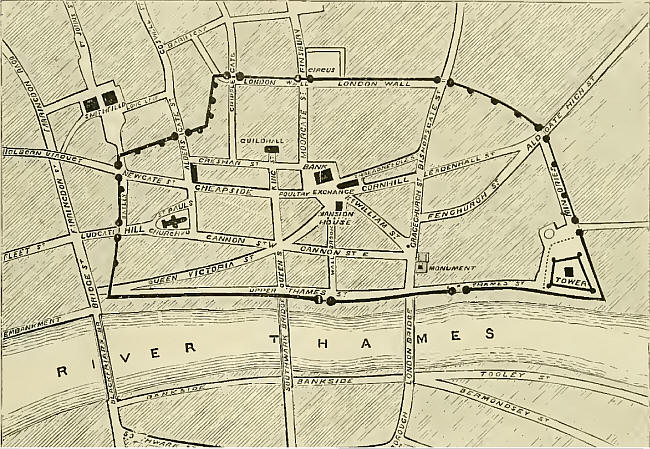

The oldest visible walls in London are the remnants of the 3.2Km 2ndC Roman landward wall, [1] [2] that surrounded the city of Londinium, now known simply as London Wall. There are other Roman walls visible, at Guildhall and the Mithraeum and Amphitheatre at Guildhall but none so large or tall as in London Wall. The bits of London Wall that survived did so as they were added too at later dates, in the Anglo-Saxon period, the Norman period and even later, to continue to defend London while some pieces were incorporated into buildings and with recent re-developments several pieces have re-appeared after centuries lost. [3]

Building London is, of course, less interested in the history of London Wall than what it was made from, and where that came from, and has already been looked at the main component, Kentish Ragstone, here https://buildinglondon.blog/2021/12/26/24-kentish-ragstone-an-introduction-to-the-most-important-historical-stone-in-london/

But the wall is not just made from Kentish Ragstone. To find out Building London has looked at 3 key sources:

1 ) The ’Inventory of the Historical Monuments in London, Volume 3, Roman London’ in 1928, which identified the wall as mainly of “… Kentish rag-stone, roughly squared and coursed on the external and internal faces, but laid in its rough state in the core and occasionally set herringbone fashion. Occasional flints also occur in the core, but no chalk or septaria has been observed. The chamfered external plinth, which is also a constant feature, is of red ferruginous sandstone, apparently also of Kentish origin … Lining with the plinth on the internal face is a triple facing-course of brick.. of the ordinary Roman bricks … These materials are set in a white mortar of extreme hardness … [and additionally] “pink mortar” … The wall stands upon a foundation … of flints and puddled clay, laid in a trench, 3 to 4 ft. deep, cut in the original surface of the ground; occasionally fragments of rag-stone are used in the place of flint… it may be stated with confidence that in its original state it contained no re-used material of any sort, the rag-stone, sandstone and brick having all the appearance of new material accumulated for the express purpose to which they were put.”. [4]

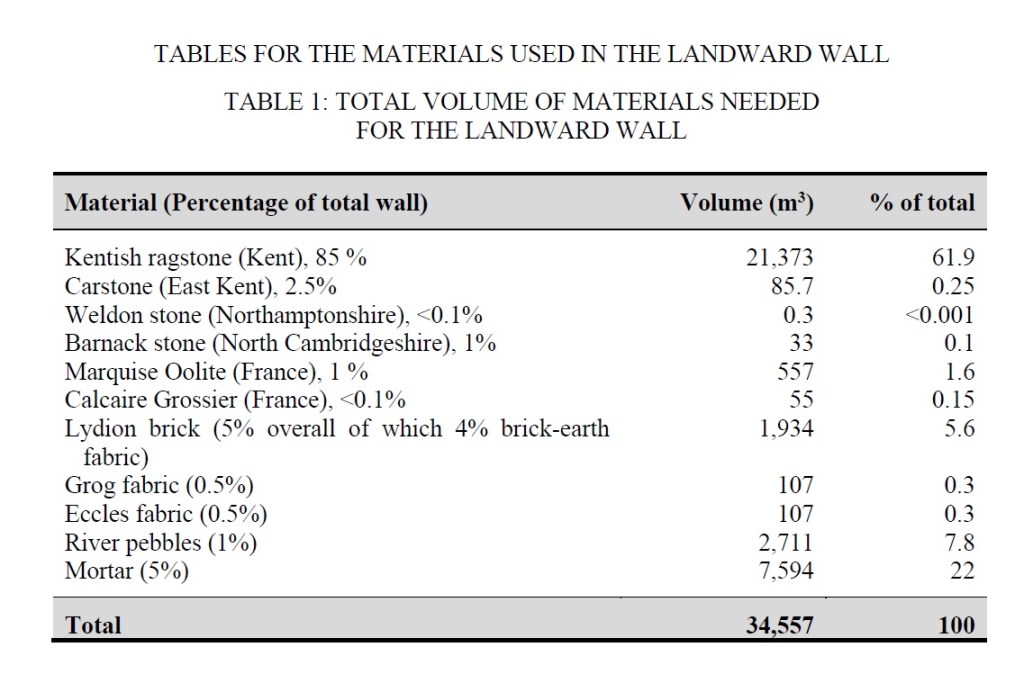

2) Simon Barker, Kevin Hayward and Penny Combe’s 2017 “Londinium’s Landward Wall: Material Acquisition, Supply and Construction”. They made estimates of the components of the wall and the percentages of that by volume:

Kentish ragstone (Kent), 62%, Carstone (East Kent), Mortar 22%, River Pebbles 7.8%, Lydion brick 5.6%, Marquise limestone, 1.6%, Barnack stone 0.1%, and tiny amounts of Weldon Stone. They also note ‘grog’, crushed pottery, [5] and Eccles fabric, brick or broken pottery from Eccles in the Medway. They also note that roughly 2/3s of the ragstone was as rubble and the other 1/3 for facing. [6]

3) And In 2019 Kevin Hayward and George Roberts did a pain stacking analysis of the stones of the Roman Wall within the site of the Tower of London, detailed in their ‘Defending Londinium and The Tower Of London: The Raw Materials. A Petrological Re-Evaluation Of The Fabric Of The Wardrobe Tower and Adjoining Roman Defensive Structures At The Tower Of London’. They also noted Kentish Ragstone, ‘ferruginous sandstone’ or Carstone, both red and yellow Lydion bricks and a variety of stones, Barnack and Weldon from the Lincolnshire Limestones and Tufa and a shelly oolitic limestone from the Cotswolds, Bibury limestone. “Further evidence for the Roman bastion is provided by the presence of sizeable blocks of tufa and a part worked banded shelly oolitic limestone (Bibury limestone) typical of the South Cotswolds. Both stone types were commonly used in Roman London (Hayward 2009; 2015).” [7]

Ragstone

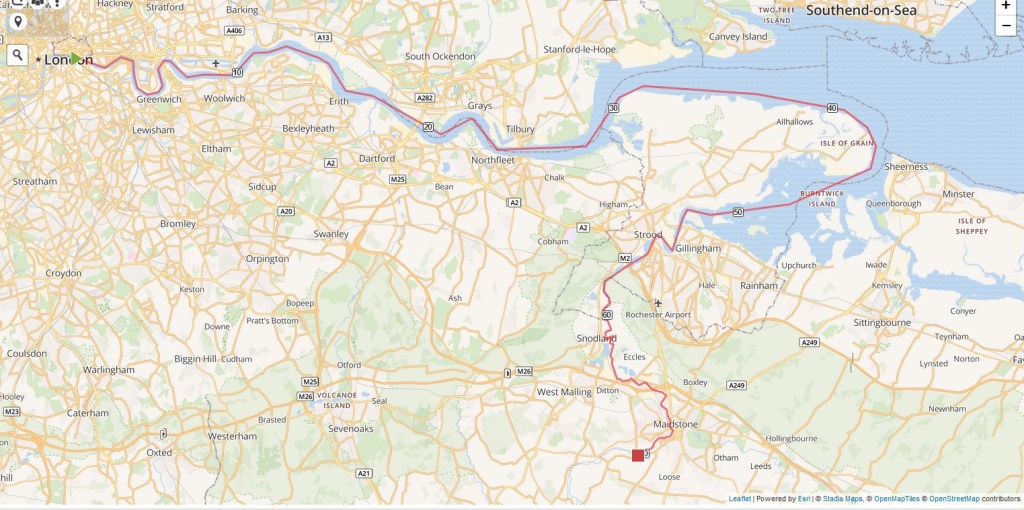

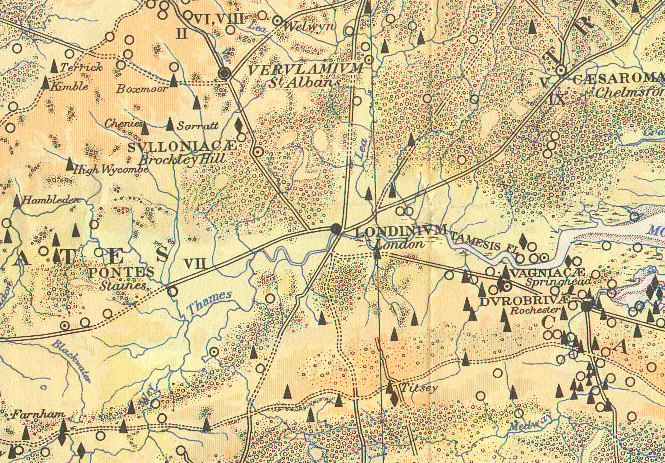

Clearly Kentish Ragstone was the main stone used. Barker et al state it was over 80% of the wall facing and 60% of the volume. Elliot identified that 1750 voyages of medium-sized merchant ships were made to transport 45,000 tonnes or 35,000 m³ or 1million facing blocks of Kentish Ragstone, a limey sandstone, or sandy limestone, the 70 river and sea miles from the Maidstone quarries to Blackfriars, where a sunken Roman ship packed with Ragstone was found in 1962, [8] Elliot estimated that the Dean Street quarry was maybe the largest Roman quarry in Europe. [9] [10] For more information see the previous Building London posts on Kentish Ragstone.

From Mapometer https://gb.mapometer.com/

Sandstone or Carstone

But London Wall has not just built with Kentish Ragstone. The Romans also used sandstone as a plinth. The 1928 Royal Commission refers to a “red ferruginous sandstone” as does Elliott.Historic England listing states that London Wall “… is known to have stood to a height of approximately 4.4m above a sandstone plinth” [11]

Barker et all don’t mention sandstone but instead Carstone from east Kent. Carrstone or Carstone is a hard conglomerate, a sandstone that has fused due to the presence of iron and pressure and so is ferruginous and hence red. [12] This must refer to stone from the Folkstone Beds in Lower Greensand [13] that are exposed at Folkestone and would have yielded some Carrstone that could be shipped the 100 mile route around the coast to Londinium.

Hayward and Roberts note at the Tower, a ” … dark brown iron-rich, gritty sandstone, .. identical to medium—coarse grade, occasionally pebbly ferruginous sandstone lenses known as ‘dogger like masses’ … that outcrop within the Folkestone Beds (Lower Cretaceous) of East Kent in areas of high ground of the North Downs between Sevenoaks and Maidstone … These include Ightham Green, Oldbury

Camp, Borough Green and Addington”

They also note “major deposits further east and close to the River Medway near Maidstone [and that] substantial deposits of Carstone were recorded in Aylesford” also on the Medway and with so much other material coming from this area, it would be a logical source. [7]

The Kent Building Stone Atlas doesn’t mention Carstone, unlike for other counties where it was much used e.g. Norfolk [14] They do though mention a Thanet Sandstone of which it states “The Roman fabric of Richborough Castle includes Thanet sandstones,” [15]

Simon Elliott places Roman sourcing at Folkestone stating “… the quarrying around Folkestone made wider use of the available extractive materials than along the Medway, with greensand, ferruginous sandstone and tufa joining the widely desired ragstone as a quarried building material. Finally, quarrying in eastern Kent was much more opportunistic, for example making use of materials exposed through the natural erosion of cliff faces.”

And he specifically notes the use of “Ferruginous Sandstone” and it’s use in London Wall stating it was “.. Quarried from the Folkestone Beds on the east Kent coast (Betts, pers. comm. 24 October 2012), Ferruginous sandstone was used across the South East, for example forming the decorative band in the north wall of the Saxon Shore fort at Richborough (Pearson, 2002b,205) and being used as a capping stone on the late 2nd century walls of London. Its notable red colour is derived from the iron-oxides which bind the grains of sand together.”

However just to complicate matters Elliott also refers to “Ironstone”, another name for Carstone,stating “In addition to its use as an iron-ore, this was also quarried locally as a building material along the foreshore of eastern Kent, being used as a material for building foundations and wall core filling at sites such as the late 1st century Villa 1 at East Cliff in Folkestone … Ironstone, named after its very high iron-oxide content, is created either by the same ferruginous process as the sandstone above, or by chemical replacement. Parfitt (pers. comm. 3 March 2014) says its use as a foundation material is based on its comparative hardness, for example when compared to Ferruginous Sandstones.” and clearly suggesting that was what was used for foundation material, i.e. plinths rather than “ferruginous sandstone”. [10]

The facing stones have been robbed on this side of the wall.

Roman bricks

Another key component of London Wall was brick, used as bonding courses to help tie the walls together. And this technique has been shown in modern tests to work! “Regarding “horizontal chaining” consisting of 2 or 3 layers of terracotta tiles (courses of bonding tiles) … It seems that we may carefully validate the hypothesis that courses of bonding tiles located in the lower sections of massive structures like bulwarks and donjons increase the internal cohesion of the lower part of the structure.” [16]

The type of bricks used were called “lydian brick (with dimensions, roughly, of 1 foot by half foot or 30 x 19cm )” [ also called Lydion or Lydium ] made by the technique of firing clay, instead of allowing it to ‘bake’ in the sun, called Oppus Testaceum. [17]

Andrea Merlini writes “The Lydion was most suitable for bonding or lacing courses found in the walls of large public buildings or defences. The purpose of these courses was twofold: when the mason building the wall found that he had reached the limit for comfortable working, a course of brick was put on to provide a new level base. Then staging was set up and the mason could proceed with his work. …

The second function of the brick courses was to bind together the face and the core, especially when the cement was still soft. Even the thickest of walls had only thin outer skins of dressed masonry, the interior being filled in with loose small stone mixed with concrete.” [18]

Surprisingly, as the area has brickearth available, the bricks don’t seem to have been made locally. By 1984 no kilns had been found in London.

“No tile producing sites have been positively located in London, but there have been occasions when they have been suspected mainly because areas of brickearth have been dug out in the Roman period, e.g. Gresham Street and Newgate Street. More recently a possible site has been found at Canons Park, Edgware .. Undoubtedly many more sites are to be expected around London even as far out perhaps as Brockley Park” [19]

This maybe changed in 2009 with a excavation at St Martins in the Fields which discovered an kiln that was “…. industrial, producing tile and brick” though it does not seem from pottery finds to have been that active in the period, the 2ndC, that London Wall was being built. [20] [21]

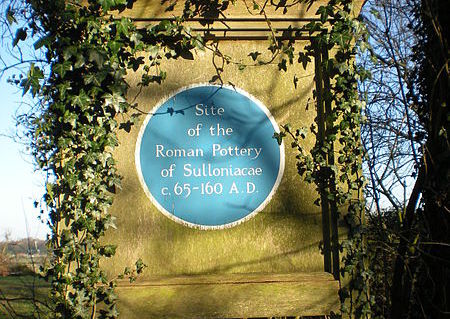

A number of sources, by looking at stamps on some of the bricks suggest some of the bricks in London Wall may have been made in Roman Sulloniacis, [22] north of modern Edgeware, up Watling Street aka the A5! [23] Other suggestions for the site of Sulloniacis include, also on Watling Street, a nearby site at Edgware Broadway. [24]

Some of the area at Brockley Hill is a Scheduled Monument and Historic England states “The pottery manufacturing site at Brockley Hill is one of the earliest known examples in Roman Britain which, at its zenith in the late first century AD, was also one of the most successful ventures of its kind. Pottery from Brockley Hill supplied London and the south east … Pottery production declined from AD 120 and finally ceased around AD 160” [25] [26]

However there’s a problem re these kilns supplying London Wall! The dates don’t match up, as London Wall was built between 190 and 225! Maybe more discoveries will show the kilns there operated into the 3rd C. More reports of excavations here and here. [27] and [28]

The scheduled site is on both sides of Brockley Hill Rd with finds made at Brockley Hill House, and more recently down the road at what is now a golf course while a marooned Blue Plaque to Sulloniacis seems to be at Wood Farm, opposite the hospital. Matt Brown at the Londonist has made the visit to see a Blue Plaque at Brockley Hill! [29]

Wikicommons Sulloniacisplaque.jpg: Stephen2810

derivative work: Dudley Miles

Another possibility would be that the bricks came from kilns at Eccles on the Medway, co-incidentally near to the Ragstone quarries, which would make sense. “… large-scale pottery manufacture in the immediate post-conquest period suggests the probability of industrial installations such as workshops, stores and wharves along the Medway” [30]And indeed Hayward and Roberts identify the yellow Lydion as coming from Eccles “Most of the bricks are in the common red sandy fabric 2815, made from local glacial clayey brickearth that was quarried in the brickfields to the north and west of the walled city.7 However, over a third of the Lydian bricks were yellow in colour and identical to the calcareous ‘Eccles’ clay fabric of the Lower Cretaceous Gault” [7]

The Roman Kilns website [31] documents pottery kiln sites in Britain, not always the same as brick kilns, and notes concentrations of kilns at Brockley Hill and also up Watling Street at Aldenham and St Albans. The sites in the City of London do not jump out as being identified as brick kilns but it again it seem strange that, with available brickearth, Lydion were not made in Londinium itself. Looking at the ‘fabric code’ for brick on the MOLA website, and checking the 2815 code as identified by Hayward and Robinson for brick in the 2nd C London Wall, points to kiln sites of “Brockley Hill (Herts) (2459A near 3006, 3006); Cannons park, Edgware, Greater London (2452), Gayners Park, Epping Forest (2459A), Park Street (Herts) (3006)” [32].

Of these, Brockley Hill is mentioned above, Gayners Park, actually Gaynes Park is a massive 19thC mansion near Epping, which is now a wedding venue. It has been identified as a site of a Roman tile kiln, and that it was on the Dunmow to London Road, [33] [34] [35] and Park Street refers to the kilns at St Albans mentioned above.

Mortar

As with all but dry-stone walls, London Wall also needed a significant amount of mortar to hold it together. And mortar needs chalk to turn into lime and that chalk could have come from relatively close, whether exposed chalk at Lewisham, Charlton or Plumstead, or further down the Thames at Northfleet where chalk is everywhere. [36] Or, maybe again from up Watling Street, where there chalk appears near were there were kilns. Again the Medway is a likely source and Roman chalk quarrying is know in this area, e.g. at Strood. [37] or from deneholes in Kent or Middlesex. [38] It almost certainly didn’t come from Chislehurst, where the idea that the caves date back to Roman times has been debunked. [39] Pink mortar is also mentioned which used ground up tiles which helped harden the mortar.

Limestones

A number of less used limestones were also mentioned by Barker et al and Hayward and Roberts.

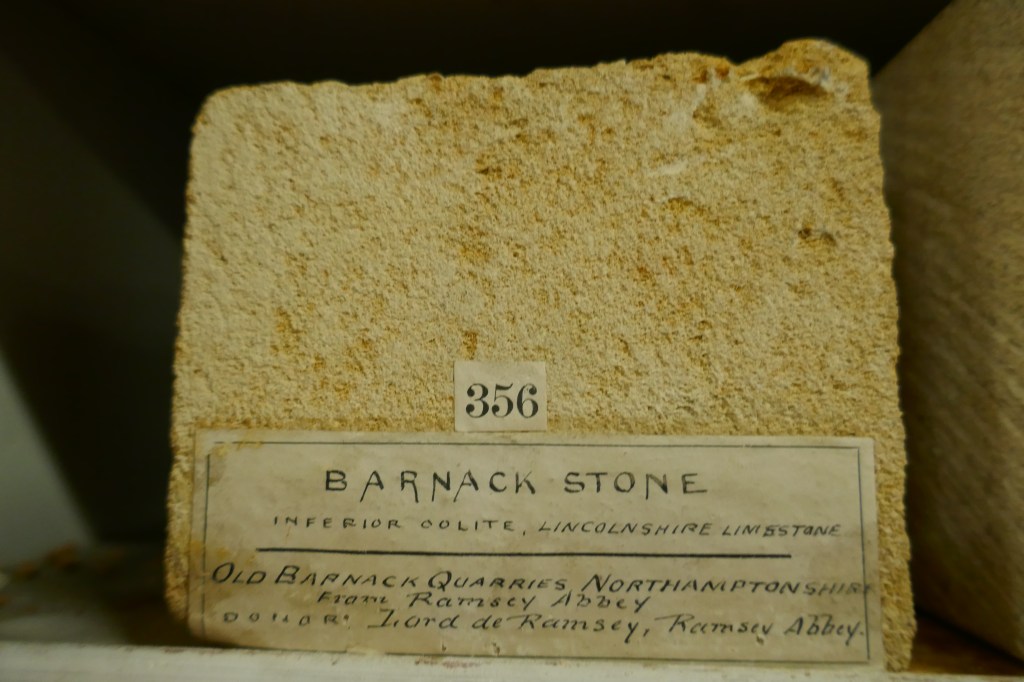

Barnack – Barnack stone [40] “ … a hard, pale buff coloured, coarse-grained, ooidal and bioclastic (shelly) limestone cemented with sparry calcite.” [41] in the Inferior Oolite Group. Upper Lincolnshire Limestone Formation, [42] is one of the Lincolnshire Limestones, often covered by Building London before e.g. https://buildinglondon.blog/2022/08/06/44-ancaster-and-its-streaky-bacon-stone-pt1/ Ancaster being a stone that Hayward and Roberts find in later, 5thC, Roman walls.

Barnack, seemingly a long way from London, was actually quite well connected to London, being a stone’s throw from Ermine Street, and just north of the busy Roman town of Durobrivae, [43] near modern day Perterborough and was accessible to London by the river system, in this case via the Nene, out through the Wash and round the coast to London. See map here [44]

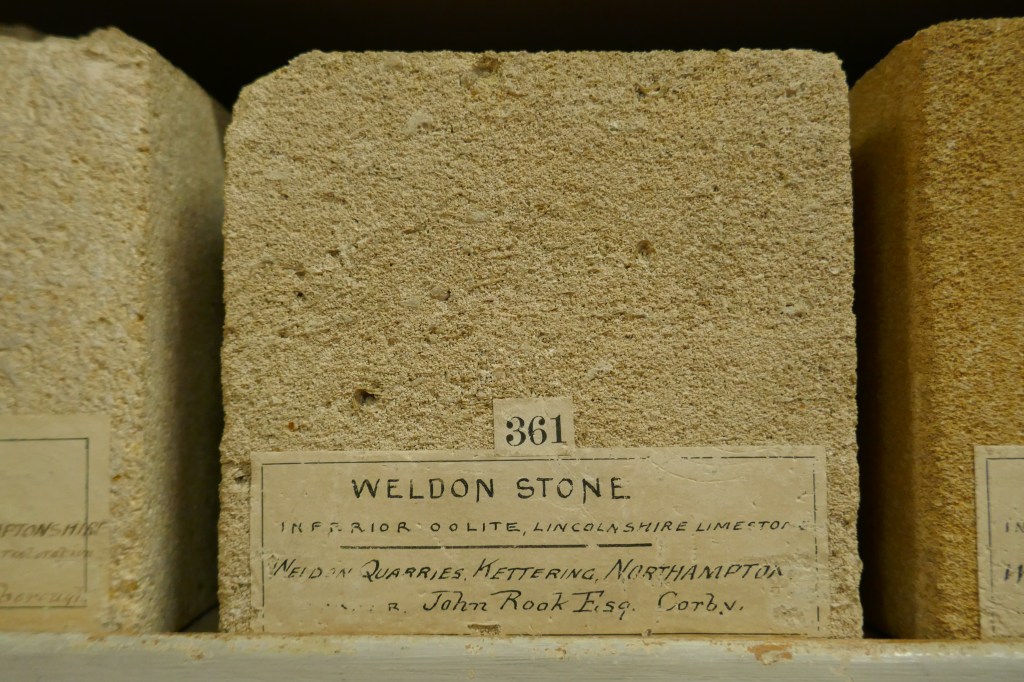

Weldon

Weldon is a similar stone to Barnack, another of the Lincolnshire Limestones but from further west. The village and ancient quarry site is now on the outskirts of Corby, more famous for it’s iron stone and iron works. [45] [46]

The Inventory of the Historical Monuments .. of Northamptonshire writing in the 1970s, states “Stone Quarries (centred SP 925890), cover some 25 hectares S. and S.W. of the village. They are cut into the Upper Lincolnshire Limestone of the Inferior Oolite Series. Many abandoned quarries and the remains of some old shafts remain, in addition to a small area still being worked. From these quarries came the well known Weldon Stone, which has been worked at least from the medieval period and probably even since Roman times” [47]

Goldholme states “The Weldon stone quarries were situated South and to the SW of the Northamptonshire Village. They covered 25HA, many abandoned quarries and shafts were still evident during the 1970’s in fact a small area was still being worked at the time. All is now abandoned!” [48]

None of the quarries appear to remain or are visible, but the site is now the public Weldon Woodland Park.

The BGS Building Stone Atlas doesn’t have Weldon as being quarried by the Romans, though they do note that the nearby Collyweston (see previous Building London) was. [49]

Marquise

This is another oolitic limestone quarried near Calais in France. It is a “Grey-white limestone; used locally in the Roman Imperial period and probably exported regionally, perhaps to Britain” [50 [51] [52 [53]

It would not have been much harder getting stone from here than anywhere else in Britain. Marquise is a few miles from Ambleteuse, where some say Julius Cesar set off from to invade Britain in AD54

“… Ambleteuse, alors nommé Ulterior Portus, où il est assez facile d’embarquer et débarquer, est le port au nord de Portus Itius que Jules César utilise pour faire partir une partie de sa flotte d’invasion de la Grande-Bretagne”. [71] It’s 120 miles by sea.

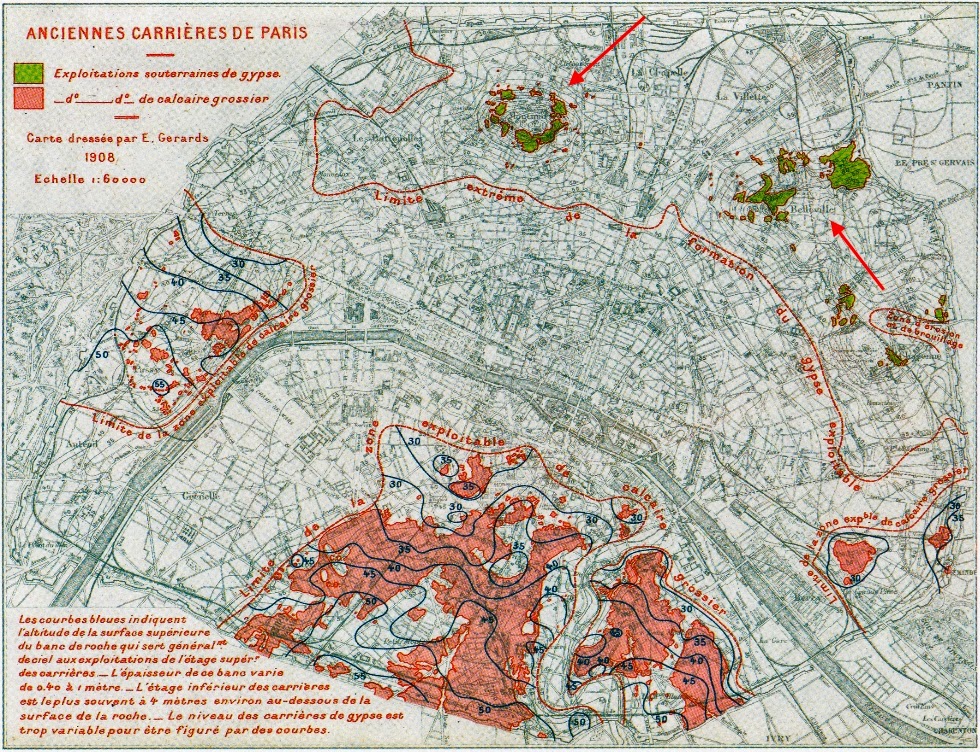

Calcaire Grossier

Or coarse limestone, now called Lutetian Limestone, [72] was quarried by the Romans in their Lutetia, or what would later become Paris “… the Left Bank was open-pit mined for its “coarse” limestone (calcaire grossier) since Gallo-Roman times.” [73]

The Roman quarries have all disappearred now [74] The Paris quarries are nearly 500 miles by the winding Seine and sea so it may be the stone was brought to London for a more specific, important reason and some leftovers ended up in the wall as rubble.

Bibury

Bibury is also an oolitic Limestone but unlike the above, part of the Great Oolite Group and of the White Limestone or Blisworth Formation. [54 [55] [56] The stone comes from a village in the Cotswolds in Gloucestershire, the most beautiful village in England according to the great William Morris. [57] The Victoria County History does not mention any Roman Quarry[58] though the BGS Gloucestershire record notes a ceased quarry but with no date. [59] Bibury Stone gets a mention in Regional Geography by Bristow and Freshney who say ““Oolites in the Ardley Member of the White Limestone Formation were worked on a moderate scale for building. The most extensive workings were at Quarry Hill [SP 101 057] between Barnsley Park and Bibury, where the beds (Bibury Stone) were worked from both open quarries and underground galleries. The surface quarries mostly date to the seventeenth and eighteenth centuries, but some could be Roman” [60]

https://commons.wikimedia.org/wiki/File:Arlington_Row_Bibury.jpg

Tufa

Tufa was also used. Tufa is another limestone but of a very different creation, being geologically recent and formed “… when carbonate minerals precipitate out of water in unheated rivers or lakes.” [61] [62]

This from Geo Essex explains in more depth: “Also of scientific interest are the hard-water springs, which are the source of crystal-clear streams that run in the cutting. Dissolved carbon dioxide (CO 2 ) in rainwater (H 2 O) soaks into the ground and has reacted with chalk (calcium carbonate – CaCO 3 ) in the boulder clay to form soluble calcium bicarbonate (Ca(HCO 3 ) 2 ). When the groundwater reaches the surface and comes into contact with the air, carbon dioxide is lost from the water and a hard deposit of cream-coloured calcium carbonate (tufa) is formed.” [63] See also [64]

To see what Tufa looks like in a wall scroll to the page on Tufa in the brilliant Essex Rock and Mineral Society’ guide to the old church walls of Essex [64] and see the walls at Waltham Abbey.

Tufa was quarried in Essex in Roman times “Tufa is a whitish or pale grey coloured limestone formed by the precipitation of calcium carbonate (lime) in or adjacent to springs issuing from calcareous rocks (such as chalk or limestone). It is often highly porous and open-textured, with up to 50% void or irregular cavity space. Blocks may be ‘fibrous’ and contain the impressions of vegetation remains, and sometimes exhibit faint traces of banding. When freshly quarried, Tufa is soft and crumbly and is easily cut into blocks suitable for use as ashlar, but upon exposure to air it hardens to become a useful, more general building stone.

Tufa was quarried at several sites near Braintree and Brentwood, but its very localised occurrence has resulted in only limited and sporadic use, mainly as a rubblestone in Medieval church walls. It was used sparingly in churches such as St.Germanus, Faulkbourne; All Saints, Vange; and St. Peter and St. Paul at Stondon Massey, Brentwood. Tufa was also notably used as facings for the Roman Balkerne Gate in Colchester.” which was built in AD 60 ish. [65]

and in Kent “… There are a number of locations in Kent, commonly associated with springs at the margin of the Hythe Formation or Chalk Group outcrops, where tufa deposits are still forming. Many older deposits have been quarried away, however, having served as sources of lime or occasionally building stone” [66]and the quarry sites would have been relatively accessible to London.

River Pebbles and flint.

Maybe, not surprisingly, pebbles are also mentioned. They were used as paths and the Thames valley would have been full of them, both in rivers and in the floodplain. Maybe surprisingly flint is not mentioned.

Visting

The London Wall has some great visiting options! Not only can you walk and explore the wall itself in London, that it is made from so many different stones, gives a whole load of options for getting out of London to discover the origins!

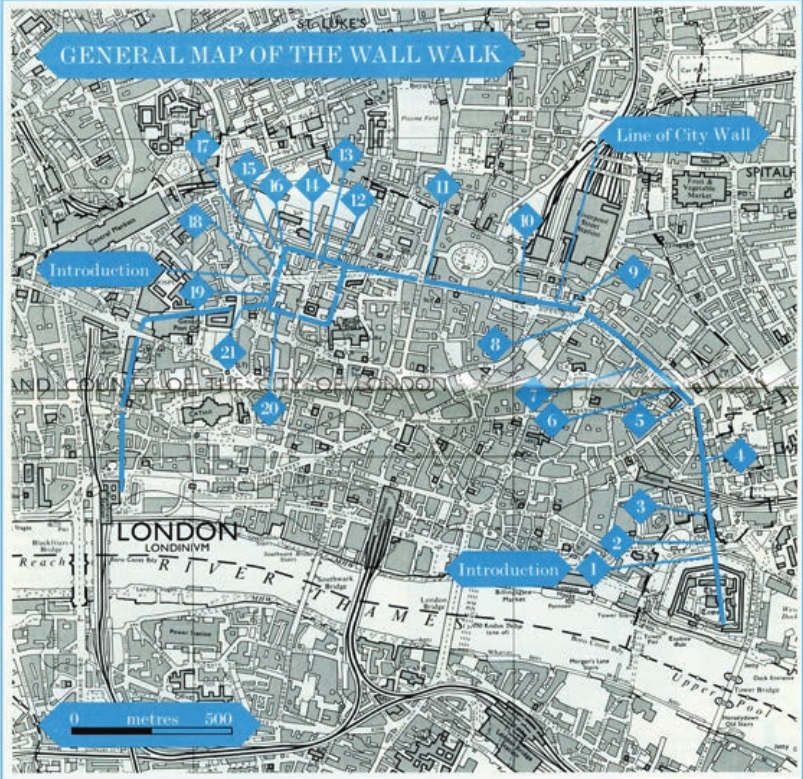

Firstly London Wall itself: there is lots online giving help for walking it

This is good https://www.timetravelrome.com/wp-content/uploads/2020/05/Roman-London-EN.pdf

This is a Google map https://www.google.com/maps/d/u/0/viewer?mid=12UtvwiGb3Pfb1BBkGQCwFfBFEGI&ll=51.51295910813191%2C-0.08887230000004909&z=15

And this is has an interactive map: https://www.heritagedaily.com/2022/07/discover-roman-london/144044

This is good too, with a self-guided walk and with the plaques. https://londonmymind.com/london-wall-walk/

And this shows all the original plaques https://www.colat.org.uk/_assets/doc/london-wall-walk-guide.pdf

And this has a list of the plaques in 2010 https://www.london-footprints.co.uk/wklondonwallroute.htm

Visiting the origins for the building materials is limited for London Wall. The Kentish Ragstone sites are definitely worth a visit, as is the whole Medway, and visiting the area has been covered in Building London before, and while many of the other stones/quarry sites are too old now for there to be anything to see, though, Bibury is very beautiful, though full of tourists. The Barnack quarries are worth a visit but will be covered in the next post.

Brockley Hill in Edgware would be a great day out from London, and while there is nothing to see, there is the Blue Plaque, and beautiful views into London, and you could try to imagine this busy Roman settlement looking down to Londinium. Maybe walk it, carrying, or not, a Roman brick! It’s c13 miles and c.4 and a 1/2 hours walk following the Roman roads, Edgware Road, Watling St, the old A5, down to Tyburn, then along Oxford Street into the City of London. Otherwise get the tube to Stanmore and walk up through the country park. [67] [68] [69]

References

[1] https://www.english-heritage.org.uk/visit/places/london-wall/History/

[2] https://en.wikipedia.org/wiki/London_Wall

[3] https://historicengland.org.uk/listing/the-list/list-entry/1018888

[4] An Inventory of the Historical Monuments in London, Volume 3, Roman London, The Royal Commission on Historical Monuments of England survey, entirely dedicated to Roman remains in London.RCHME Inventory Volumes. Originally published by His Majesty’s Stationery Office, London, 1928

https://www.british-history.ac.uk/rchme/london/vol3/pp69-82

[5] https://en.wikipedia.org/wiki/Grog_(clay)

[6] https://www.cambridge.org/core/journals/britannia/article/abs/londiniums-landward-wall-material-acquisition-supply-and-construction/7C12270731C5F30FA1C4BD5D89C0A104

[7] Hayward and Roberts Transactions of the London & Middlesex Archaeological Society . 2019, Vol. 70, p105-128.

[8] https://www.heritagegateway.org.uk/Gateway/Results_Single.aspx?uid=405065&resourceID=19191

[9] Ragstone to Riches: How Kentish ragstone built Roman London by Dr Simon Elliott

https://www.youtube.com/watch?v=YnOUT1SDfvg&ab_channel=visitthecity

[10] Elliott, Simon (2017) Change and continuity in the exploitation of natural resources (such as stone, iron, clay and wood) in the principal areas of industrial activity in Kent (namely the Weald, Folkestone region and upper Medway Valley) during the Roman occupation. Doctor of Philosophy (PhD) thesis, University of Kent. 2016 https://kar.kent.ac.uk/61960/1/186Simon%20Elliott%20PhD%20Thesis.pdf

Elliot’s book “Ragstone to Riches, Imperial Estates, metalla and the Roman military in the south east of Britain during the occupation” is available here https://www.barpublishing.com/ragstone-to-riches.html

[11] https://historicengland.org.uk/listing/the-list/list-entry/1018888

[12] https://en.wikipedia.org/wiki/Carrstone

[13] https://en.wikipedia.org/wiki/Lower_Greensand_Group

[14] https://www2.bgs.ac.uk/mineralsuk/download/EHCountyAtlases/Norfolk_Building_Stone_Atlas.pdf

[15] https://www2.bgs.ac.uk/mineralsuk/download/EHCountyAtlases/Kent_Building_Stone_Atlas.pdf

[16] http://www.ancientportsantiques.com/ancient-port-structures/reinforced-concrete/

[17] https://www.aeternitas-numismatics.com/single-post/main-roman-masonry-techniques-3rd-part.

[18] “The Roman construction techniques of building during the Imperial Age, with a particular focus on bricks and tiles” Andrea Merlini 2016 https://www.academia.edu/26952464/Masters_Degree_thesis_in_Roman_British_Archaeology_The_Roman_construction_techniques_of_building_during_the_Imperial_Age_with_a_particular_focus_on_bricks_and_tiles_PhotoScan_3D_models_of_my_case_studies_concerning_ancient_Roman_walls_and_buildings_in_England

[19] The Production and distribution of brick and tile in Roman Britain Alan McWhirr PhD Uni of Leicester 1984 https://leicester.figshare.com/articles/thesis/The_production_and_distribution_of_brick_and_tile_in_Roman_Britain/10087739

[20] https://archaeologydataservice.ac.uk/archives/view/romangl/maprecord.cfm?id=8066

[21] https://archaeologydataservice.ac.uk/archiveDS/archiveDownload?t=arch-1352-1/dissemination/pdf/G_London/GL8061_SLO75016.pdf

[22] https://en.wikipedia.org/wiki/Sulloniacis

[23] https://www.cambridge.org/core/journals/britannia/article/abs/official-tilestamps-from-london-which-cite-the-province-of-britain/44CCD31E29A78B7DC9524FFE0168B7EF

[24] https://www.roman-britain.co.uk/places/sulloniacis/

[25] Brockley Hill Romano-British pottery and settlement https://archaeologydataservice.ac.uk/archives/view/romangl/maprecord.cfm?id=8005

[26] https://historicengland.org.uk/listing/the-list/list-entry/1018006?section=official-list-entry

[27] http://www.lamas.org.uk/images/documents/Transactions59/081-152%20Brockley%20Hill.pdf

[28] http://www.lamas.org.uk/images/documents/Transactions59/061-080%20Roman%20Harrow.pdf

[29] https://londonist.com/london/history/sulloniacis-plaque-stanmore-roman-london

[30] https://archaeologydataservice.ac.uk/archives/view/romangl/maprecord.cfm?id=9060

[31] https://romankilns.net/

[32] https://www.mola.org.uk/roman-ceramic-building-materials-fabrics-dating-fabric-groups-sources-and-distribution-codes

[33] https://www.efdclocalplan.org/wp-content/uploads/2018/03/EB900-EF-Historic-Environment-Characterisation-Study-Essex-County-Council-2015.pdf

[34] https://historicengland.org.uk/listing/the-list/list-entry/1123952?section=official-list-entry

[35] https://gaynespark.co.uk/

[36] https://webapps.kent.gov.uk/KCC.ExploringKentsPast.Web.Sites.Public/SingleResult.aspx?uid=MKE114542

[37] https://www.friendsofbroomhill.org.uk/history

[38] https://en.wikipedia.org/wiki/Denehole

[39] https://kurg.org.uk/chalk-mines

[40] https://en.wikipedia.org/wiki/Barnack

[41] https://www2.bgs.ac.uk/mineralsuk/download/EHCountyAtlases/CambridgeshireBuildingStoneAtlas.pdf

[42] https://archaeologydataservice.ac.uk/archives/view/stones_ahrb_2005/cfm/Public/details/RockDetails.cfm?RockCode=BARNKR

[43] https://en.wikipedia.org/wiki/Durobrivae_(Water_Newton)

[44] http://oxrep.classics.ox.ac.uk/docs/Stone_Quarries_Database.pdf

[45] http://oxrep.classics.ox.ac.uk/docs/Stone_Quarries_Database.pdf

[46] https://www.mindat.org/loc-297733.html

[47] ‘Weldon’, in An Inventory of the Historical Monuments in the County of Northamptonshire, Volume 2, Archaeological Sites in Central Northamptonshire (London, 1979), pp. 164-166. British History Online http://www.british-history.ac.uk/rchme/northants/vol2/pp164-166

[48] https://goldholme.com/2020/02/20/what-happened-to-the-quarries-that-built-cambridge/

[49] https://www2.bgs.ac.uk/mineralsuk/download/EHCountyAtlases/Northamptonshire_Building_Stone_Atlas.pdf

[50] http://oxrep.classics.ox.ac.uk/databases/sites/france/marquise_quarry/

[51] http://oxrep.classics.ox.ac.uk/docs/Stone_Quarries_Database.pdf

[52] https://www.dorsetbuildingstone.org/pas-de-calais.html

[53] https://www.mindat.org/loc-262247.html

[54] https://webapps.bgs.ac.uk/lexicon/lexicon.cfm?pub=WHL

[55] https://webapps.bgs.ac.uk/lexicon/lexicon.cfm?pub=BWL

[56] https://en.wikipedia.org/wiki/White_Limestone_Formation

[57] https://en.wikipedia.org/wiki/William_Morris

[58] https://www.british-history.ac.uk/vch/glos/vol7/pp21-44#h3-0003

[59] https://www2.bgs.ac.uk/mineralsuk/download/EHCountyAtlases/GloucestershireSources.xlsx

[60] https://chacklepie.com/ascorpus/vol10_chap4.pdf

[61] https://en.wikipedia.org/wiki/Tufa

[62] https://bathgeolsoc.org.uk/journal/articles/1982/1982_Tufa.html

[63] http://www.geoessex.org.uk/wp-content/uploads/2020/09/UTT-Flitch-Way-Ballast-Pit-and-Tufa-Springs-LoGS-Revised-March-2020.pdf

[64] http://www.thegeologytrusts.org/pub/wp-content/uploads/2010/document-downloads/Quaternary-Deposits-in-England.pdf

[65] http://www.erms.org/church-walls—a-closer-look.html

[66] https://www2.bgs.ac.uk/mineralsuk/download/EHCountyAtlases/essex_Building_Stone_Atlas.pdf[67] https://www2.bgs.ac.uk/mineralsuk/download/EHCountyAtlases/Kent_Building_Stone_Atlas.pdf

[68] https://www.harrowncf.org/Wood_Farm_leaflet.pdf

[69] https://www.harrowncf.org/SCP_home.html

[70] https://www.harrowncf.org/PW_home.html

[71] https://fr.wikipedia.org/wiki/Ambleteuse

[72] https://en.wikipedia.org/wiki/Lutetian_limestone

[73] https://written-in-stone-seen-through-my-lens.blogspot.com/2014/04/geological-legacies-of-paris-basin-part.html

[74] https://written-in-stone-seen-through-my-lens.blogspot.com/2014/06/geological-legacies-of-paris-basin-part.html

Leave a comment